Electron Beam & Laser Welding Experts

Medical | Aerospace | Automotive | Sensor

Inspection & Testing

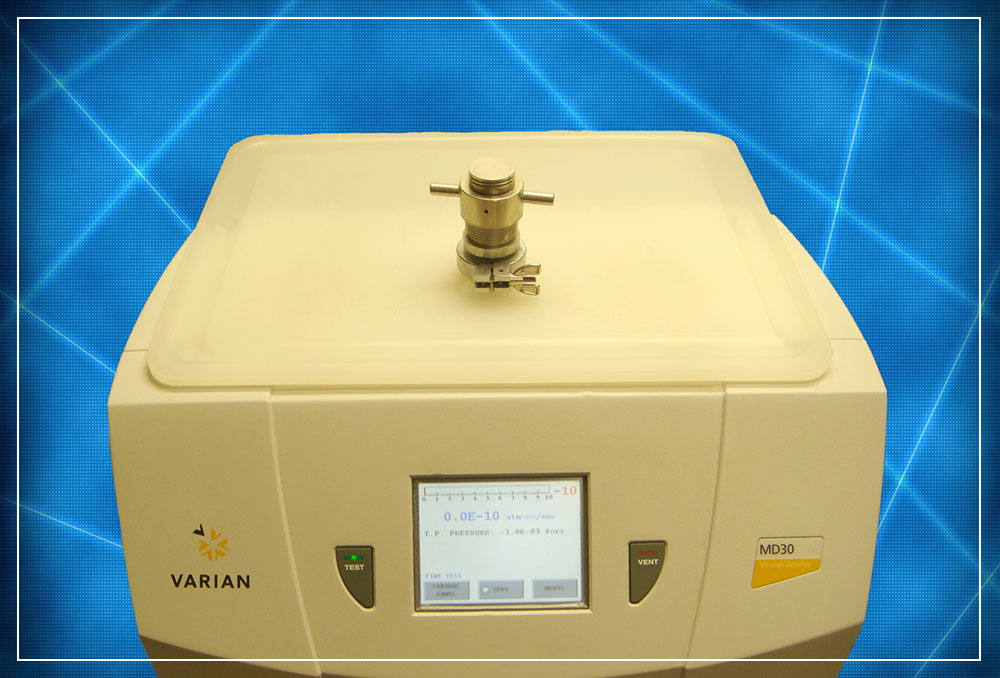

Electron Beam Engineering maintains a high standard of inspection and testing equipment for electron beam welding and laser welding requirements. Helium leak testing and helium bomb testing are two of the most frequently performed tests to verify that a welded component is hermetically sealed. Leak testing is typically certified per MIL-STD-883H Method 1014.13 test condition A4 for evacuated containers, and MIL-STD-883H Method 1014.13 test condition A1, the bomb testing method for sealed containers. We can also certify to ASTM-E493, E498 or E499.

Our calibrated computerized Inspection Microscope System offers a monitor display with travelling/measuring of X-Y stage, with a built in camera function to photograph the sectioned weld samples. Text can be added to the images to notate measurements or other significant details, which can then be easily emailed to customers who would like copies of the images.

Other testing we regularly have performed by approved network of suppliers / partners include: radiographic inspection, dye penetrant inspection, magnetic particle inspection, ultrasonic inspection, micro-hardness testing and tensile testing.

to 1X10-10 atm./cc/sec

(for sealed components)